Industry IOT,LEUZE sensors,Motion control system,durable guide-rails and durable pneumatic parts to achieve an optimal balance of intelligence and cost-effectiveness in the machine.

Email:admin@amamachine.com

Whatsapp:+86 17758110836

MAIN TECHNICAL PARAMETERS

|

MODEL |

RA-600MF Automatic Rigid Box Maker |

|

Max.paper size(L×W) |

620mm×1040mm |

|

Min.paper size(L×W) |

70mm×130mm |

|

Paper thickness |

100-300g/㎡ |

|

Cardboard thickness of inner box |

0.8-3mm |

|

Max.Rigid-box size(L×W) |

500×400mm |

|

Min.Rigid-box size(L×W) |

100×50mm |

|

Rigid-box Height |

12-130mm |

|

Turn-in Depth |

10-80mm |

|

Corner-folding Length |

10-80mm |

|

Max.Paper-pile height |

550mm |

|

Max.Cardboard-pile height |

1380mm |

|

Max.cardboard qty.at case station |

5pcs |

|

Case size |

Max.540mm×950mm,Min.70mm×130mm |

|

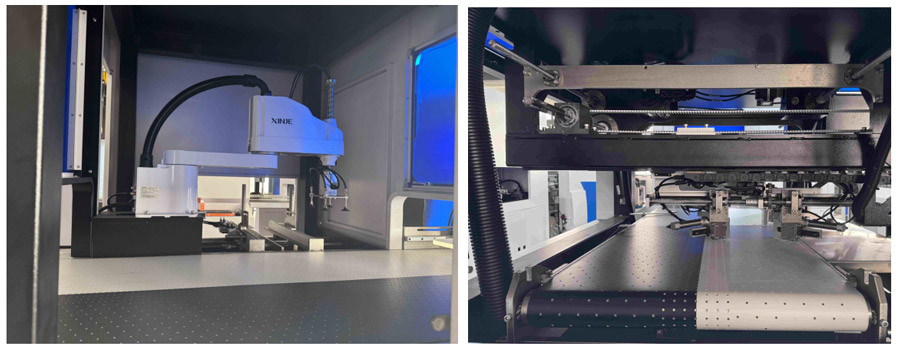

SCARA |

XINJE |

|

Working speed |

15-23pcs/min. |

|

Precision |

0.1-0.2mm |

|

Motor Power |

12KW |

|

Air supply |

50L/min.0.6Mpa |

|

Voltage |

AC380V,50Hz,3-PH |

|

Dimension(L×W×H) |

6.5m×5m×3.1m |

|

Machine Weight |

5500kg |

Features:

◆ Post-suck paper feeding system and Double sheet detection system to avoid two or more sheets feeding trouble;

◆ Intelligent glue-viscosity adjusting system and servo controlling for the gluing rollers to get even gluing and make debugging-work simpler;

◆ Visual system only 3-position setting required, more intelligent and quicker;

◆ Remote on-line support for the Visual system and automatic visual troubles alarm-display on visual computer, faster and easier for after-sale trouble shooting; 2-station for both Case and Box Positioning.

◆ Servo controlling for the corner-pasting section to make mold-replacing work much easier;

◆ Box wrapping system adopts box-clamping feeding to avoid paper scratch which applies to producing luxury packaging,jewelry box,phone box,chocolate box and so on.

◆ Industry IOT,LEUZE sensors,Motion control system,durable guide-rails and durable pneumatic parts to achieve an optimal balance of intelligence and cost-effectiveness in the machine.